1.General

1.1 Vehicle control unit (VCU) is the core of the whole control system as the central control unit of new energy vehicle. VCU is responsible for normal driving, braking energy feedback, energy management of engine and power battery, network management, fault diagnosis and treatment, vehicle status monitoring, etc., so as to ensure the normal and stable operation of the whole vehicle under the condition of good power, high economy and reliability.

1.2 Battery Management System BMS (battery management system) is an important link between the vehicle power battery and electric vehicle. It is mainly for intelligent management and maintenance of each battery unit, preventing the battery from overcharging and over discharge, prolonging the service life of the battery and monitoring the status of the battery.

1.3 It can be said that the performance of the vehicle controller (VCU) and battery management system (BMS) directly determines the performance of the new energy vehicle, and plays a mainstay role.

1.4 With the popularity of new energy vehicles, the corresponding production line scale is expanding day by day. How to test the VCU and BMS products off line quickly and effectively is an urgent problem for suppliers to solve. Based on many years of production line testing experience, VCU and BMS design experience, the company designed special off-line detection equipment.

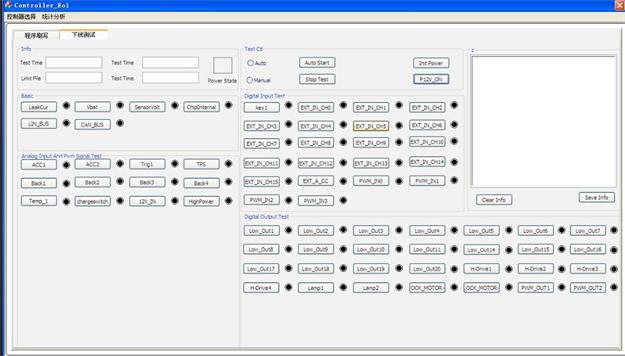

2.Equipment Function Characteristics

2.1 The software human-computer interaction interface, on the human-computer operation interface, the tester can realize one key automatic test or custom manual test.

2.2 All hardware of test equipment shall be placed on the cabinet to ensure the integration and aesthetics of test equipment.

2.3 Data can be traced and production data can be stored in local database.

2.4 The system can configure some functions of independent automatic test logic, and can calibrate function threshold or fault parameters to verify different working conditions.

2.5 The test process is highly automated, and the production line personnel can use the equipment after simple training.

2.6 Platform production line test software integrates user management, equipment management, test sequence editing, data query and other functions, which is convenient to operate and requires low skill requirements for equipment maintenance personnel.

3.Supported test items

3.1 For offline production line detection equipment, typical test items supported are as follows:

(1) Power supply test.

(2) Can communication test.

(3) Flash test.

(4) Static current acquisition.

(5) Analog quantity test.

(6) Digital quantity test.

(7) High and low output test.

(8) Fault injection test.

(9) Boundary condition test, etc.